CLIENT’S NEED

The comprehensive digitalization of a company is an action aimed at increasing the productivity of said company. This increase in productivity also has a very short-term return that, in most cases, is achieved in 6 or 12 months. Business digitalization is not something new, it has been talked about for a few years. However, despite its obvious benefits, it has taken a pandemic for many companies in our country to decide to go digital.

Carthago Seguridad Marítima (CSM) is one of the few national companies that has the necessary accreditations, and distinctions to carry out maintenance, repair, and tuning tasks on vessels of all sizes. However, many of the daily maintenance tasks for such vessels are still carried out manually and heavily on paper.

The extensive experience we have at Biyectiva in the field of Artificial Intelligence means that we can profoundly improve the productivity of CSM. On the one hand, a digitalization of the on-site inspection processes of vessels was needed. This includes digitalization, detection, and extraction of relevant fields in forms, checklists, and their subsequent incorporation into management software. In addition, although part of the visits to the clients' vessels are mandatory and regulated by law, a good part of the controls of the safety elements (life rafts, fire extinguishers, etc.) can be monitored automatically and remotely.

On the other hand, another great need for CSM was the automation of the maintenance of the security systems of the vessels through IoT. This makes it possible to greatly reduce face-to-face reviews by CSM staff and improve service by anticipating potential failures. These results are included in a software module developed to manage incidents.

CHALLENGES AND DIFFICULTIES

The comprehensive digitalization of a company covers different areas of its activity, almost always resulting in a great diversity of challenges and difficulties. Regarding the digitalization of the on-site inspection processes of vessels, the main complexity was in the requirements of the tasks. Checklists can contain anything from marks (ticks, crosses, lines) to arbitrary text, all filled out by hand and with very different calligraphies. A great deal of work was needed to homogenize the way in which the different operators filled out the checklists.

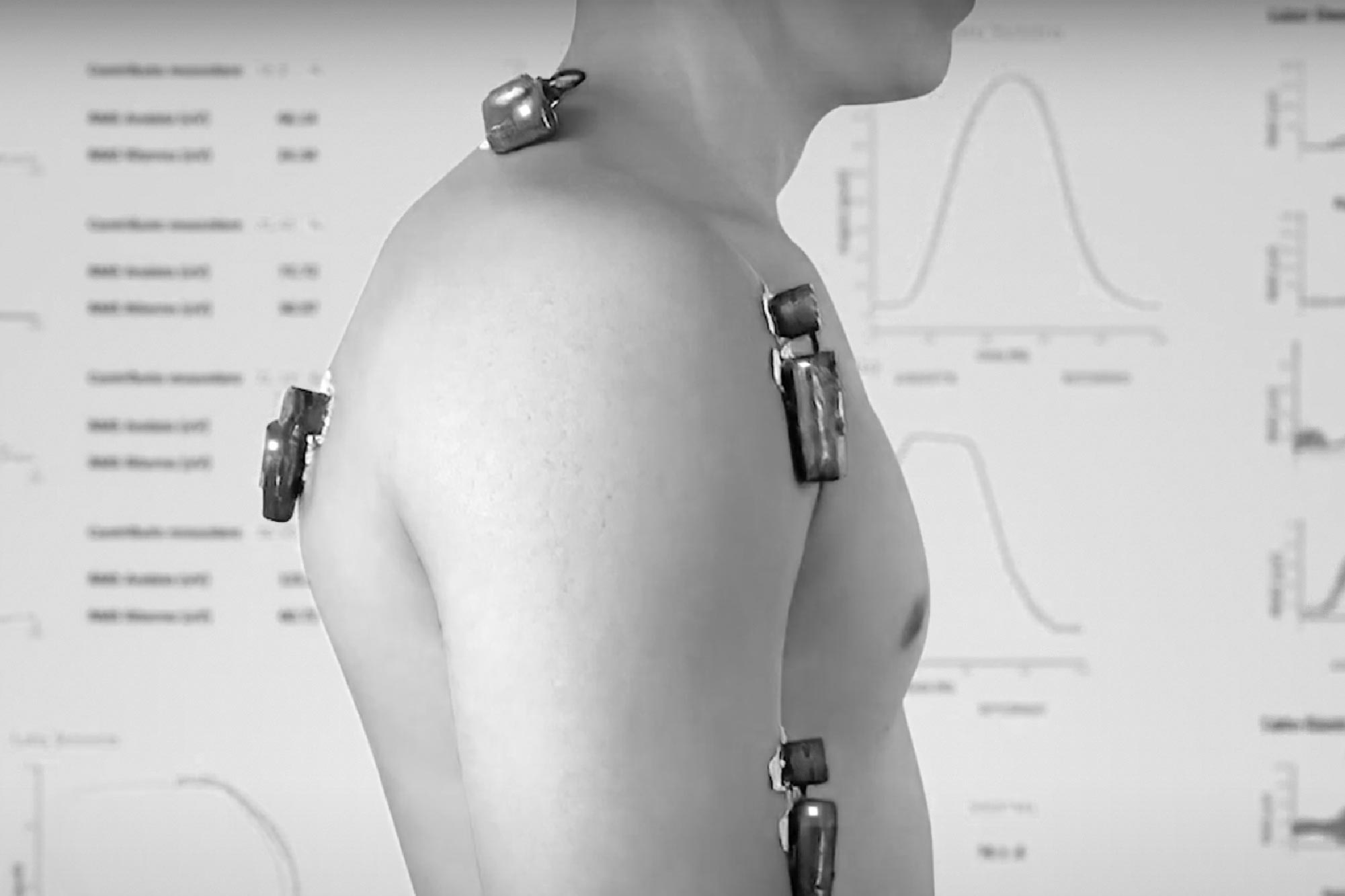

For the automation of the maintenance of security systems through IoT, one of the main complications was the design of the hardware for the sensorization and capture of the different physical magnitudes to be measured. Since these sensors are placed directly on the safety elements, (rafts and fire extinguishers) and given the hostile operating environment, an essential requirement was to be able to work with electronics capable of withstanding very adverse humidity and temperature conditions.

From the point of view of communication, the presence of multiple metal structures (ship frame, engines, pipes) proved to be a very important problem when it came to providing coverage to all the ship's sensors. The proposed solution contemplated, from the beginning, the use of robust communications that tolerated extreme working conditions.

SOLUTIONS

The Biyectiva team designed a software, supported by Computer Vision techniques, that automatically extracts fields from checklists and forms: handwritten text, marks, forms, etc. Thus, the CSM workers only have to take a photo of the checklist (completed by the field technicians and which generates a carbon copy that must be delivered to their client) so that it is incorporated into the digital data lake

Inevitably, sometimes checklists and forms contain garbled text or errors. To prevent this data from ending up in CSM's digital systems, a verification station is incorporated together with the automatic recognition system. In it, a worker from the CSM administrative department can supervise, in seconds, the extraction of dozens of checklists. If everything is correct, it will give the green light and this information will be definitively incorporated into the CSM ERP. If not, you can modify those data that have been filled in wrongly.

From the IoT side, the early warning system verifies that all the security systems of the vessels are in perfect condition. To do this, each smart thing (security elements that have IoT technology) reports to a hub placed inside the boat. This report is made using LoRa wireless technology, which is very robust and enjoys a low level of consumption. Each hub in turn sends the aggregated and pre-filtered information to the CSM central via 3G - available worldwide without the need for its own network infrastructure. Once in the CSM central, warnings are generated if any of the security systems fail or an inappropriate drift in their behavior is being detected. For the detection of trends, forecasting techniques based on Machine Learning were used. For example, if it is seen that a certain element follows a temperature trend that could end in fire, early warning is given before it happens.

RESULTS

Despite the fact that this project has an important component of IoT and Machine Learning, what the client perceives is a strong increase in productivity thanks to the ease and agility that allows resources to be optimally focused.

On the other hand, there is a significant reduction in the hard work of manually digitalizing work tickets. Just by taking a photo of the checklist, it is automatically incorporated into the client's ERP software. The second source of increased productivity comes from the minimization of unnecessary visits to maintain the safety equipment of the vessels. Thanks to the IoT, CSM can considerably reduce the number of visits to clients' vessels, being notified in advance if an element malfunctions or has to be replaced.

Comprehensive digitalization is not something exclusive to large companies. This change allows companies to make the most of the resources available to them, making it ideal for SMEs that have fewer resources than large companies and multinationals.